Every mission-critical cleanroom or controlled environment relies on one often-invisible professional: the controlled environment certifier. National Controlled Environment Certifier Day on November 5 honors the experts who test, validate, and document airflow, containment, and cleanliness so patients stay safe and products meet expectations. From HEPA integrity to airflow visualization, from pressure cascades to ISO classifications, certifiers safeguard the standards that modern medicine, microelectronics, and research depend on. This day spotlights their technical rigor, commitment to safety, and relentless attention to detail—qualities that rarely make headlines yet keep some of the world’s most sensitive work possible. Join CETA in thanking the professionals who ensure cleanrooms are truly clean.

History of National Controlled Environment Certifier Day

The roots of controlled environment certification trace back to the mid-20th century, when clean air and contamination control became essential to aerospace, defense, and nascent semiconductor manufacturing. A watershed moment arrived in 1960, when engineer Willis Whitfield introduced the modern laminar-flow cleanroom—technology that revolutionized contamination control by sweeping particles away from sensitive processes. As cleanrooms expanded across industries, the need for standardized testing grew, giving rise to methods for measuring particulates, verifying filter performance, and documenting airflow behavior.

In the following decades, international consensus matured. The ISO 14644 series (first published in 1999) provided a common language for cleanroom classification and testing. In healthcare, sterile compounding and aseptic processing accelerated demand for qualified facilities. Regulators such as the U.S. Food and Drug Administration emphasized contamination-control strategy, aseptic behavior, and the importance of robust, defensible data—work that certifiers enable through routine testing and thorough reporting.

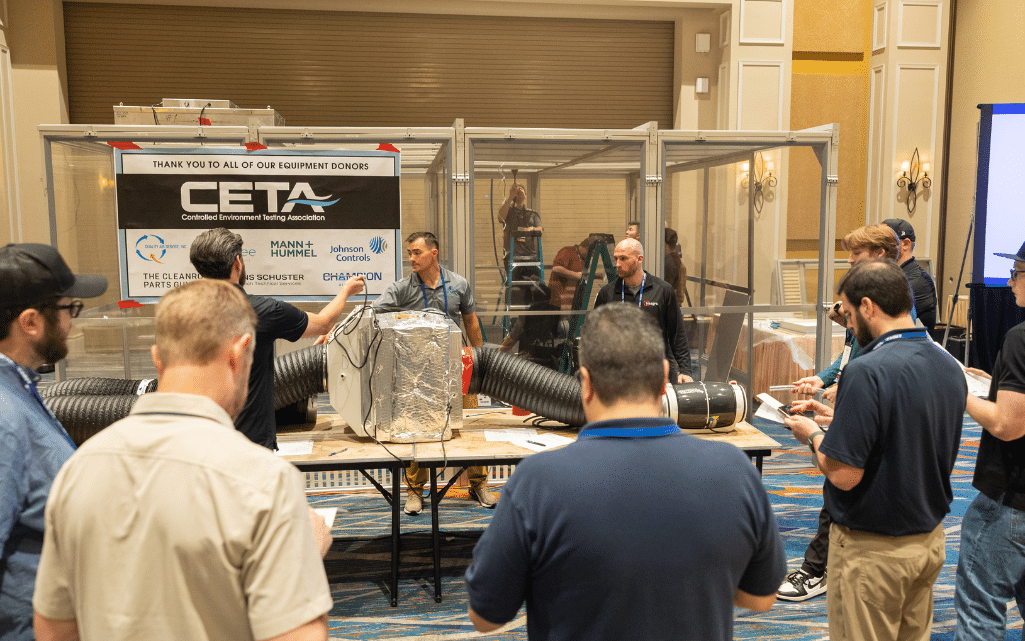

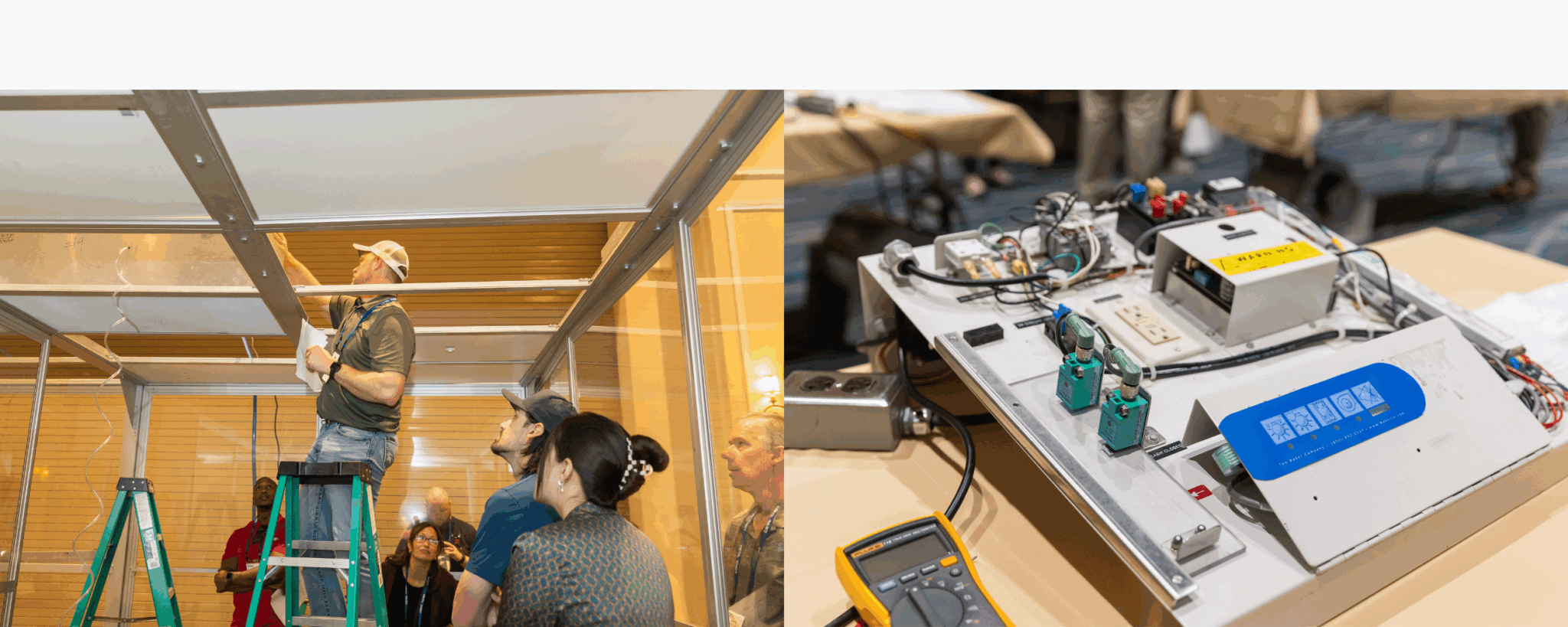

As the field professionalized, certifiers organized around shared practices, mentorship, and credentialing. CETA (Controlled Environment Testing Association) brought together field certifiers, manufacturers, and laboratories to exchange methods, refine procedures, and champion excellence. Through training, standardization efforts, and credentialing programs, the role of the controlled environment certifier evolved from “good to have” to “business critical.” Today, certifiers are essential in pharmaceuticals and biotechnology, medical device production, microelectronics, hospitals and pharmacies, and advanced research facilities.

National Controlled Environment Certifier Day was created to spotlight this vital work and to recognize those whose signatures and stamps of approval carry real-world consequences: product quality, regulatory compliance, and, ultimately, patient safety. The day encourages organizations to share gratitude, invest in continuing education, and elevate public understanding of what certification means. It is also a call to the next generation to join a profession where precision matters and where day-to-day diligence shapes outcomes that few see but many depend on.

National Controlled Environment Certifier Day timeline

Engineer Willis Whitfield debuts the modern laminar-flow cleanroom, transforming contamination control.

Standard test methods for HEPA/ULPA integrity, airflow, and particle counting become common practice (e.g., evolving U.S. FED-STD-209 series and early IEST recommended practices; leak testing widely implemented with photometer methods).

The Controlled Environment Testing Association (CETA) is formally established to promote quality assurance and improve testing quality.

The first parts of ISO 14644 are published, defining international cleanroom classifications and testing/monitoring frameworks.

Standards and guidance for sterile compounding and hospital cleanrooms gain prominence; certifier roles expand (e.g., adoption and use of USP <797> in U.S. healthcare).

Major USP <797> revision becomes official on November 1, 2023, underscoring airflow visualization, monitoring, and documentation rigor.

CETA inaugurates an annual celebration recognizing the professionals who certify our most critical spaces.

National Controlled Environment Certifier Day FAQs

What is a controlled environment certifier?

A trained professional who tests, documents, and certifies cleanrooms, biosafety cabinets, and other controlled spaces to confirm they meet defined standards and regulatory expectations.

Who recognizes National Controlled Environment Certifier Day?

CETA established the day to honor certifiers across healthcare, life sciences, microelectronics, and research. Companies, hospitals, pharmacies, and labs are encouraged to participate.

Why do certifiers matter to patients?

Properly certified environments reduce contamination risk in sterile compounding and aseptic manufacturing, which directly impacts patient safety and therapeutic quality.

How is this different from routine maintenance?

Certification is standardized testing and documentation—airflow, particles, pressure, filter integrity—performed at defined intervals or after changes, providing objective evidence of control.

How to Observe National Controlled Environment Certifier Day

Share your #ControlledEnvironmentCertifierDay story

Post photos or short videos from your latest certification, airflow visualization, or EM work. Tag #ControlledEnvironmentCertifierDay and #CleanroomCertified to spotlight your team and mentors.

Pledge to advance the profession

By becoming a CETA member, you are expected to actively promote and encourage the highest level of integrity within the certification industry and commit to the use of the highest quality standards and practices for the certification industry. Already a member? Encourage colleagues to join CETA!

Host a lunch-and-learn

Organize a 45-minute session on airflow visualization, HEPA leak testing, or reading certification reports. Invite cross-functional partners—QA, pharmacy, engineering—to build shared understanding.

5 Facts About National Controlled Environment Certifier Day

Particle-size precision

Certifiers routinely measure airborne particles down to 0.5 micrometers to verify ISO cleanliness classes.

Airflow artists

“Smoke studies” and airflow visualization help certifiers confirm unidirectional flow and reveal hidden turbulence.

Filters with proof

HEPA and ULPA filters aren’t just installed—they’re leak-tested and documented to ensure real performance.

Pressure matters

Tiny pressure differentials are monitored to keep clean zones protected from contamination.

Data = compliance

Certification reports create the objective evidence regulators, auditors, inspectors, and surveyors expect for ongoing state of control.

Why National Controlled Environment Certifier Day is Important

They protect patients and products

Certifiers verify that sterile compounding pharmacies, biopharma suites, and device lines meet strict environmental controls. Their work reduces the risk of contamination, recalls, and patient harm.

They turn standards into everyday practice

From ISO classifications to aseptic guidance, certifiers translate complex requirements into testable criteria and actionable results. They help facilities prove—not just assume—compliance.

They build trust across the supply chain

Reliable, repeatable certification builds confidence among clinicians, manufacturers, regulators, and the public. When a certifier signs off, stakeholders know the environment is fit for purpose.

National Controlled Environment Certifier Day dates

| Year | Date | Day |

|---|---|---|

| 2026 | November 5 | Thursday |

| 2027 | November 5 | Friday |

| 2028 | November 5 | Sunday |

| 2029 | November 5 | Monday |

| 2030 | November 5 | Tuesday |