- Today

- Holidays

- Birthdays

- Reminders

- Cities

- Atlanta

- Austin

- Baltimore

- Berwyn

- Beverly Hills

- Birmingham

- Boston

- Brooklyn

- Buffalo

- Charlotte

- Chicago

- Cincinnati

- Cleveland

- Columbus

- Dallas

- Denver

- Detroit

- Fort Worth

- Houston

- Indianapolis

- Knoxville

- Las Vegas

- Los Angeles

- Louisville

- Madison

- Memphis

- Miami

- Milwaukee

- Minneapolis

- Nashville

- New Orleans

- New York

- Omaha

- Orlando

- Philadelphia

- Phoenix

- Pittsburgh

- Portland

- Raleigh

- Richmond

- Rutherford

- Sacramento

- Salt Lake City

- San Antonio

- San Diego

- San Francisco

- San Jose

- Seattle

- Tampa

- Tucson

- Washington

New Unsinkable Metal Tubes Could Revolutionize Ships and Renewable Energy

Superhydrophobic design traps air bubbles to keep tubes afloat, even when severely damaged.

Published on Feb. 8, 2026

Got story updates? Submit your updates here. ›

Scientists at the University of Rochester have developed a process to create aluminum tubes with a superhydrophobic interior surface that traps air bubbles, allowing the tubes to stay afloat even when heavily damaged. This breakthrough could lead to more resilient ship hulls, floating platforms for coastal infrastructure, and innovative wave energy harvesting systems.

Why it matters

This unsinkable tube technology represents a significant advancement in materials science that could revolutionize maritime engineering, enable new forms of floating infrastructure, and provide a promising renewable energy solution. By creating surfaces that repel water, the researchers have found a way to maintain buoyancy even in the face of severe damage, addressing a longstanding challenge in ship design and opening up new possibilities for floating structures and wave energy conversion.

The details

The researchers used an etching process to create micro- and nano-pits on the interior surface of aluminum tubes, making them superhydrophobic and able to trap stable air bubbles when submerged. Even with multiple holes punched in the tubes, the trapped air keeps them floating. The team has tested tubes up to half a meter long and says the technology could be scaled up to create larger, load-bearing platforms. They've also demonstrated how these superhydrophobic tube rafts could be used to harvest energy from ocean waves.

- The research was published in February 2026 in the journal Advanced Functional Materials.

The players

Chunlei Guo

A professor of optics and physics at the University of Rochester's Institute of Optics and a senior scientist at the university's Laboratory for Laser Energetics, who led the research team that developed the unsinkable metal tube technology.

University of Rochester

The institution where the research on unsinkable metal tubes was conducted, through its Institute of Optics and Laboratory for Laser Energetics.

What they’re saying

“Importantly, we added a divider to the middle of the tube so that even if you push it vertically into the water, the bubble of air remains trapped inside and the tube retains its floating ability.”

— Chunlei Guo, Professor of Optics and Physics (University of Rochester)

“We tested them in some really rough environments for weeks at a time and found no degradation to their buoyancy. You can poke huge holes in them, and we showed that even if you severely damage the tubes with as many holes as you can punch, they still float.”

— Chunlei Guo, Professor of Optics and Physics (University of Rochester)

What’s next

The researchers plan to continue exploring the long-term durability of the superhydrophobic coating in harsh marine environments, as well as optimizing the etching process and investigating the use of alternative materials to further improve the technology.

The takeaway

This breakthrough in unsinkable metal tube design has the potential to transform maritime engineering, enable new forms of floating infrastructure, and provide a promising renewable energy solution through wave energy harvesting. By creating surfaces that repel water, the researchers have found a way to maintain buoyancy even in the face of severe damage, addressing a longstanding challenge in ship design and opening up new possibilities for the future.

Rochester top stories

Rochester events

Mar. 7, 2026

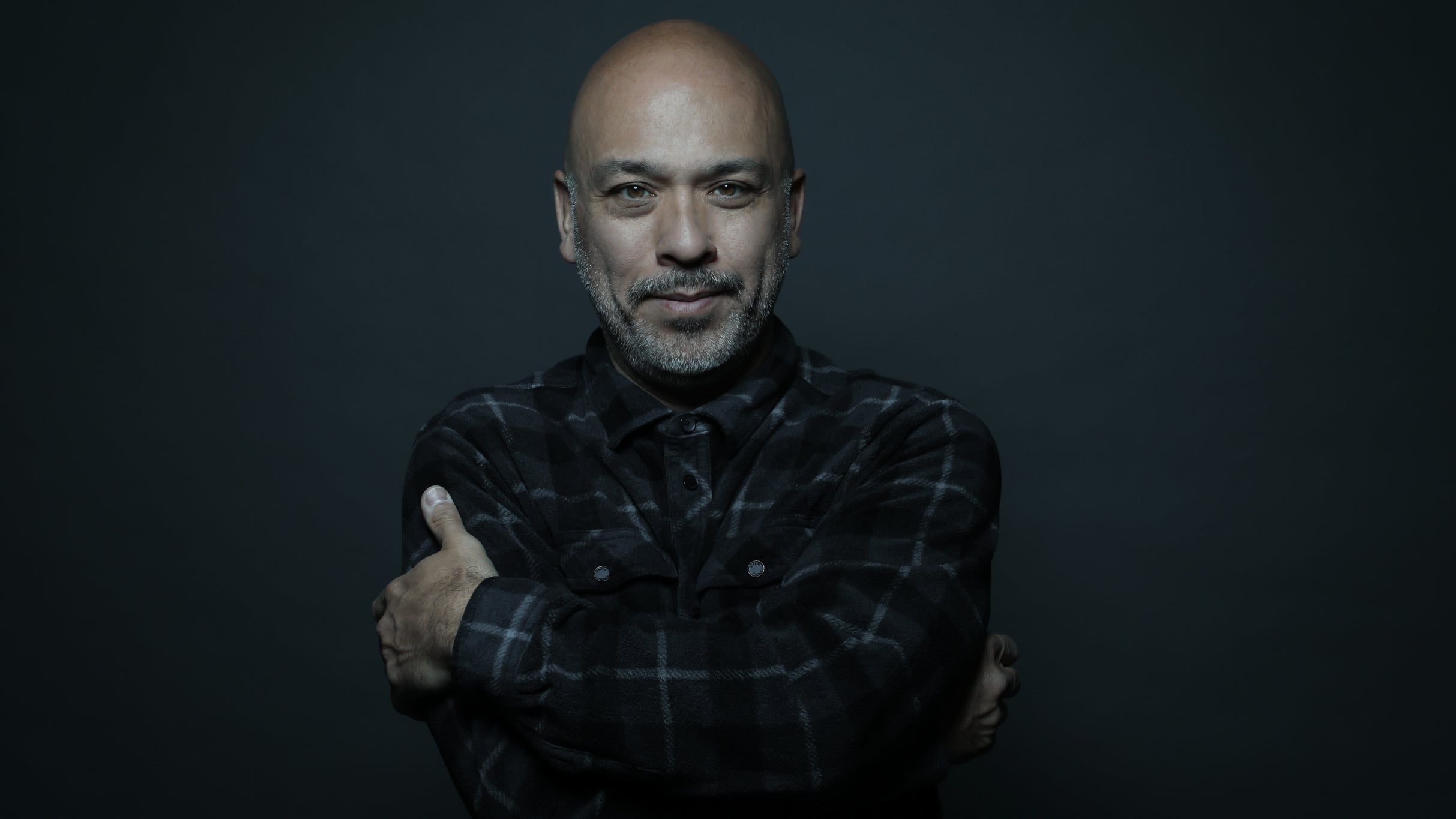

Jo Koy: Just Being Koy TourMar. 10, 2026

Lyle Lovett and John Hiatt - Together On Stage